| Into | Ukuqamba | Iyasakaza |

| Inqubo | Ukuqamba kuyinqubo yokusebenzisa umshini wokubumba ukwenza insimbi ingenalutho ikhiqize ukuguquguquka kwepulasitiki, ukuze kutholwe izakhiwo ezithile zemishini, ukuma nosayizi. Ngokusebenzisa ukubumba kungaqeda amaphutha e-ascast ensimbi enqubweni yokuncibilikisa, kuthuthukise i-microstructure, kugcine ukugeleza kwensimbi okuphelele, ngakho-ke izakhiwo zemishini zokubumba ngokuvamile zingcono kunokusakaza impahla efanayo. Iningi lezingxenye ezibalulekile zomshini ezidinga umthwalo omkhulu kanye nesimo esibucayi sokusebenza sisebenza izingxenye zokubumba. | Ukusakaza kuyinqubo yokubeka insimbi ewuketshezi endaweni yokuphonsa, ngemva kokupholisa nokuqiniswa ukuze kutholwe izingxenye ezidingekayo. |

| Okubalulekile | Izinto zokwakha zisebenzisa kabanzi insimbi eyindilinga, insimbi yesikwele. kukhona i-carbon steel, i-alloy steel, insimbi engagqwali kanye nensimbi engeyona insimbi esetshenziswa kakhulu endaweni yendawo kanye nemboni yokunemba. | Ukusakaza ngokuvamile kusebenzisa insimbi empunga, insimbi ecibilikile, insimbi ekhangisiwe ethambile, kanye "nensimbi ecijile. Insimbi evamile engasansimbi: ithusi, ithusi, ithusi le-wuxi, i-aluminium alloy njll. | Ngaphansi kwesimo esilinganayo, i-forgingmetal inokusebenza okungcono kwezakhi zemishini, kuyilapho ukubunjwa kuphakeme ekubumbeni. |

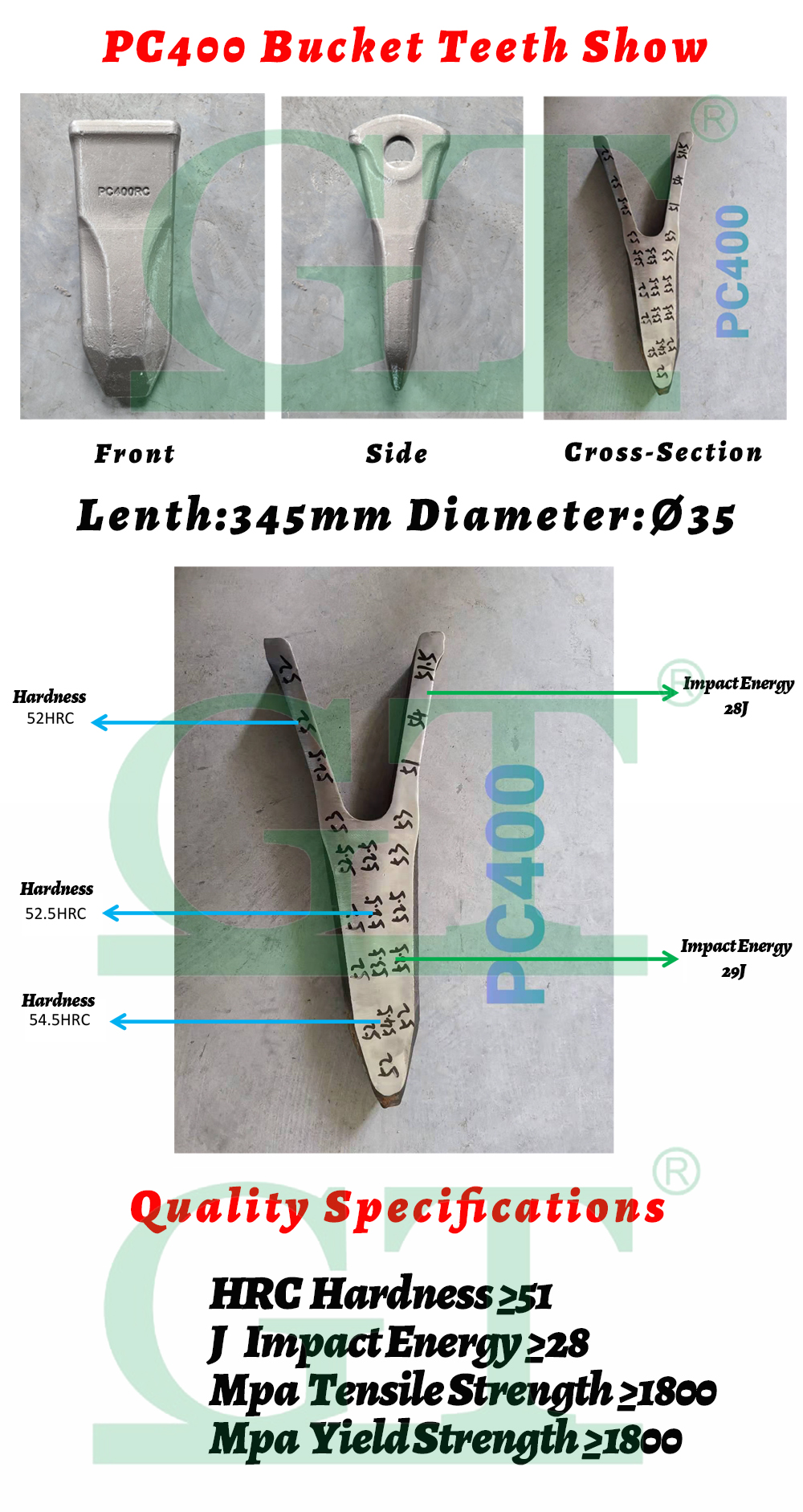

| Ukubukeka | Ukusabela kwe-oxidation yensimbi yokubumba ngesikhathi senqubo yokushisa ephezulu kuzodala okusanhlamvu okuncane kwe-kylin ebusweni bamazinyo ebhakede akhiwe. Futhi njengoba ukubunjwa kwenziwa ngokubumba, ngemva kokukhipha i-slot yemvume esikhunjeni, kuzoba nomugqa wokuhlukanisa emazinyweni ebhakede akhiwe. | Kukhona umkhondo wesihlabathi kanye nokuphonsa i-kiting ebusweni bokuphonsa amazinyo ebhakede. |

| Impahla Mechanical | Inqubo yokuqamba ingaqinisekisa ukuqhubeka kwefayibha yensimbi, futhi igcine ukugeleza kwensimbi okuphelele, iqinisekisa izakhiwo ezinhle zokusebenza nempilo ende yesevisi yamazinyo ebhakede, okuyinto inqubo yokuphonsa engenakuqhathaniswa. | Uma kuqhathaniswa nezingxenye zokulingisa, ukwakheka kwensimbi kanye nezakhiwo zemishini zingathuthukiswa ngemva kokufojwa. Inhlangano yokuphonsa ngemuva kokwenza ukuguqulwa okushisayo, i-crystal bulky yasekuqaleni kanye ne-columnar okusanhlamvu ishintsha ibe yizinhlamvu ezinhle, kanye nenhlangano efanayo ye-isometric recystallization, vumela ukwakheka kokuhlukaniswa kwangempela ngaphakathi kwe-ingot, i-osteoporosis, ukufakwa kwe-porosity slag nokunye okuhlangene ukuze kube eduze kakhulu, ngaleyo ndlela kuthuthukise ipulasitiki yensimbi kanye nezakhiwo zemishini.

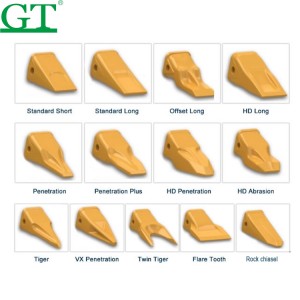

Ukuqamba ukuthola isimo esidingekayo ngokucindezela insimbi ngokusebenzisa i-plastic deformation, ngokuvamile ngesando noma ingcindezi. Inqubo yokuqamba ihlinzeka ngesakhiwo esihle se-granular, futhi ithuthukisa izici ezibonakalayo zensimbi, ngokusetshenziswa okungokoqobo, idizayini efanele ingaqinisekisa ukugeleza kokusanhlamvu lapho kubheke khona ingcindezi enkulu. Nakuba ukubunjwa kuwukuthola izinto zokwakha insimbi ngokusebenzisa zonke izinhlobo zezindlela zokuphonsa, okungukuthi ukubeka insimbi ewuketshezi esibunjeni esilungisiwe ukuze uthole umumo othile, usayizi kanye nezakhiwo, ngokuncibilikisa, ukuphonsa, umjovo noma enye indlela yokuphonsa, kanye nokuthuthumela ngemva kokupholisa, ukuhlanza nokwelashwa kokugcina. |