I-Excavator Attachment Excavator I-Rock Bucket Crusher Bucket Jaw Plate

Ibhakede le-Crusher livame ukufakwa ku-excavator, kusetshenziswa amandla we-hydraulic we-excavator, ethembele ekuncinzeni okuqinile kwemihlathi engenhla nangaphansi ukuchoboza itshe, elingakwazi ukuchoboza imfucuza yamatshe nokwakhiwa, futhi lingahlukanisa ngokushesha imigoqo yensimbi kukhonkolo, enganciphisa ukuphathwa kwamabhulokhi kakhonkolo endaweni yephrojekthi.

Izindleko zokuhamba nezinye zobunjiniyela ezibangelwa itshe elichotshoziwe zenze ukuthi imfucuza kakhonkolo igaywe kabusha ngokuqondile futhi iphinde isetshenziswe endaweni yokwakha.

amabhakede ethu e-crusher futhi ahambisana nama-excavators angamathani ayi-10 kuye kwangama-20 (njengePC200 yethu). Lokhu kuyenza ilungele amasayithi aphakathi nendawo kuya kwezikhudlwana adingeka ukuchoboza futhi agaywe kabusha izinto ezifana nokhonkolo, itiyela, itshe, i-hardcore, i-tile, idwala, noma ingilazi.

I-1.Isimiso sokusebenza: Ukwamukela isethi egcwele egcwele engenisiwe yemidwebo nobuchwepheshe, i-motor kanye ne-eccentric shaft yokuxhumana kwesakhiwo, ngokusebenzisa amandla okukhipha injini ye-hydraulic, i-flywheel ye-drive kanye ne-eccentric shaft rotation, ukuze ipuleti lomhlathi lifinyelele ukunyakaza okuhambisanayo okuqhubekayo, ngepuleti lomhlathi eligxilile ukwenza umphumela oqhubekayo we-extrusion ingcindezi yokuchoboza. Ngokuhlehlisa ukuzungeza, izinto ezivalekile zingakhululwa kalula.

2.Isiqiniseko sekhwalithi: Ngaphezu kwepuleti lomhlathi kanye nokuhlanganiswa kwepuleti lendlebe elixhumayo elishintshwayo, konke kwenziwa ngensimbi yaseSweden Hardox, enomqondo wokuklama wesisindo esilula namandla aphezulu okugqokekayo ebhakedeni elichotshozwayo. Izingxenye ezibalulekile zehydraulic zonke zihlinzekwa yiJapan(Zonke zingenisiwe)

3.I-Jaw Plate: Ipuleti lomhlathi elinamandla okumelana nokugqokwa lihlukaniswa libe ipuleti elinyakazayo eliphezulu kanye nepuleti elingashintshi elingashintshaniswa elinye nelinye, futhi izingxenye ezingemuva nezangaphambili nazo zingashintshwa ukuze kukhuliswe ukusetshenziswa kwepuleti lomhlathi futhi kuncishiswe imvamisa yokushintsha. Isikhathi sokushintshwa kwepuleti yomhlathi ongaphezulu singamahora angama-500-600, ipuleti lomhlathi ongezansi amahora angama-800-1000. Isikhathi sokushintsha sihlukile ngokusekelwe ebukhuni bezinto ezichotshozwayo.

4.Usayizi wokulungisa: Usayizi wembobo yokukhipha bungalungiswa kalula ukusuka ku-20mm ukuya ku-120mm ngokukhuphula noma ukunciphisa inombolo nokushuba kwepuleti lokulungisa endaweni yokukhipha ibhakede le-crusher.

"5.Mayelana nokuphumayo: usayizi wembobo yokukhipha ngokuvamile ulungiswa ku-30-50mm, ngokusho kobukhulu, ukuqina kwento echotshoziwe kanye nesimo sokumba, okukhiphayo okujwayelekile kungamathani angu-15-22 ngehora, ukulungiswa okukhudlwana usayizi ochotshoziwe, okuphumayo okuphezulu."

6.Ukufakwa: Sebenzisa ipayipi lesando eligxotshwa umshini wokumba ukuze uxhume ipayipi likawoyela elingenayo nephumayo (intshi engu-1) yebhakede eligxobayo, kanye nepayipi elilodwa lokubuyisela uwoyela ukuze libuyele ngqo ethangini elikhulu.

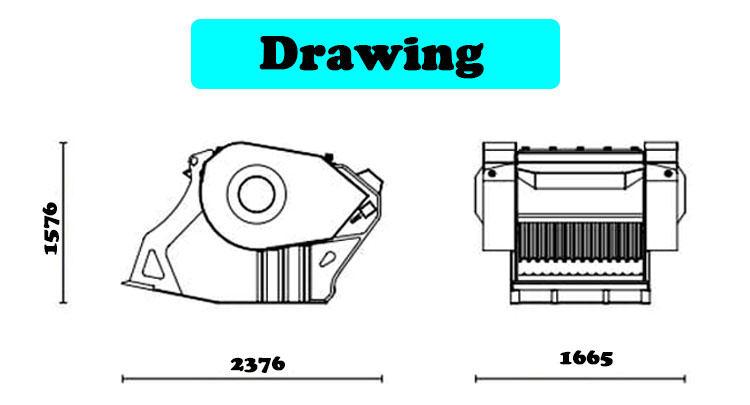

| Imodeli | Usayizi wokudla A*B (mm) | Ingcindezi yokusebenza Mpa | Ukugeleza kwamafutha L/min | Isivinini esijikelezayo (r/min) | Usayizi wokulungisa L*W*H (cm) | Isisindo (KG) | Faka isicelo ku-(Ton) | |

| I-PSD-200 | 70 * 50 cm | 23-25 | 260 | 350-450 | 250*117*160 | 2600 | 20-30t | |